Why Process Safety Management is Crucial for Industrial Safety

Introduction: The Role of Process Safety Management in Industrial Operations

Industrial facilities handle complex processes that involve hazardous materials, high-pressure systems, and volatile chemicals. Ensuring safe operations is not just about regulatory compliance but also about protecting lives, assets, and the environment.

Process Safety Management (PSM) plays a vital role in mitigating risks, preventing accidents, and maintaining operational stability. It provides a structured approach to identifying, analyzing, and controlling process-related hazards in industries such as oil & gas, chemicals, manufacturing, and power plants.

This article explores why PSM is critical for industrial safety, its key elements, and how industries can strengthen their safety frameworks to minimize risks.

What is Process Safety Management and Why Does it Matter?

Process Safety Management (PSM) refers to a systematic approach aimed at identifying, assessing, and mitigating risks associated with industrial processes. It focuses on preventing chemical releases, fires, explosions, and equipment failures that could lead to catastrophic incidents.

Key Reasons Why PSM is Crucial for Industrial Safety:

-

Prevents Major Industrial Accidents – By identifying potential hazards early, PSM reduces the likelihood of serious incidents.

-

Ensures Compliance with Safety Regulations – Many industries are required to implement PSM programs to meet government and international safety standards.

-

Protects Workforce and Assets – A well-executed safety program minimizes injuries, fatalities, and damage to infrastructure.

-

Reduces Downtime and Financial Losses – Preventing accidents means fewer production halts, equipment failures, and liability issues.

-

Strengthens Corporate Reputation – Companies with strong safety measures gain trust from stakeholders, investors, and employees.

By integrating Process Safety Management, industries can create a safer, more efficient work environment while ensuring long-term sustainability.

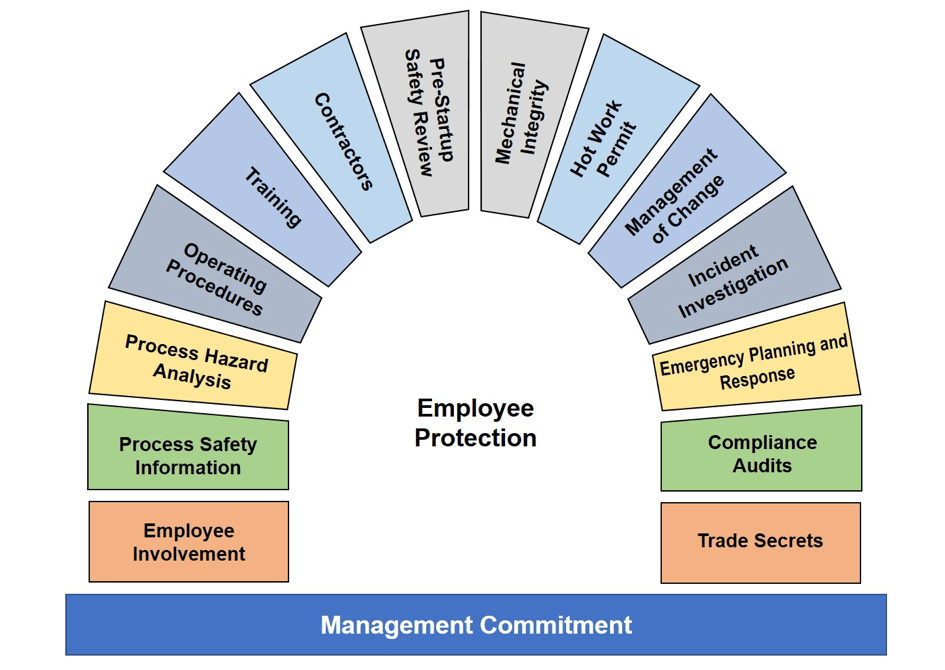

What are the Key Elements of Process Safety Management?

For an effective Process Safety Management program, industries must implement a comprehensive framework that covers all aspects of operational safety.

Core Elements of PSM:

-

Process Hazard Analysis (PHA) – Identifying potential hazards within industrial processes.

-

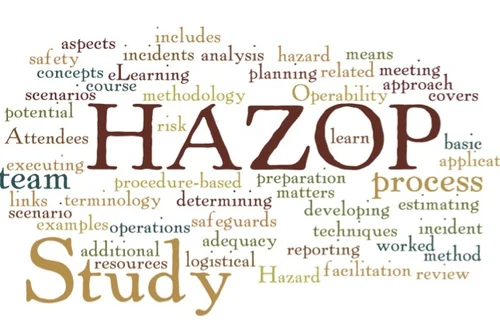

Hazard and Operability (HAZOP) Study – A structured approach to evaluating potential deviations in process operations. Learn more about Hazop Study.

-

Standard Operating Procedures (SOPs) – Establishing clear safety guidelines for operations.

-

Mechanical Integrity and Maintenance – Ensuring equipment is regularly inspected and maintained.

-

Emergency Response Planning – Preparing for potential incidents with well-defined response strategies.

-

Training and Competency Development – Educating employees on safety procedures and hazard management.

-

Incident Investigation and Reporting – Analyzing past accidents to prevent future occurrences.

-

Audit and Compliance Checks – Regular Safety Audits to assess adherence to safety protocols.

By implementing these PSM components, industries can significantly enhance their ability to detect and prevent operational risks.

How Do Industrial Accidents Occur Without Proper Process Safety Management?

Industrial accidents often result from lack of risk assessment, poor maintenance, inadequate safety procedures, and human errors. The absence of a robust PSM system increases the probability of:

-

Chemical spills and toxic gas leaks, leading to environmental hazards.

-

Explosions due to uncontrolled reactions or equipment failures.

-

Fire outbreaks caused by ignition of flammable materials.

-

Structural failures due to corrosion, pressure build-up, or overheating.

One of the most effective ways to prevent fire hazards is by conducting regular Fire Audits to ensure compliance with fire safety protocols.

Industries that neglect PSM measures not only put lives at risk but also face financial penalties, legal consequences, and reputational damage.

How Can Process Safety Management Improve Workplace Safety?

A strong Process Safety Management system enhances workplace safety by introducing structured protocols for handling hazardous operations.

Ways PSM Improves Industrial Safety:

✔ Risk Identification and Control – Ensures potential hazards are detected early.

✔ Prevention of Equipment Malfunctions – Ensures machines and tools function safely.

✔ Reduces Human Errors – Provides safety training to enhance workforce awareness.

✔ Encourages a Culture of Safety – Promotes responsibility and accountability among employees.

✔ Regulatory Compliance – Ensures businesses meet local and international safety regulations.

With the implementation of PSM strategies, industries can protect workers, prevent financial losses, and enhance operational efficiency.

What are the Challenges of Implementing Process Safety Management?

Despite its advantages, Process Safety Management implementation can be challenging due to operational complexities and resource constraints.

Common Challenges in PSM Implementation:

-

Lack of Trained Personnel – Many organizations struggle with a shortage of skilled safety professionals.

-

High Implementation Costs – Establishing a PSM system requires financial investment in safety training, equipment, and audits.

-

Resistance to Change – Employees may resist new safety protocols due to familiarity with existing practices.

-

Inconsistent Monitoring and Compliance – Without regular audits, safety measures may deteriorate over time.

To address these challenges, organizations can seek expert guidance from professional safety advisors. Engaging a Safety Consultant ensures industries receive customized solutions tailored to their operational needs.

How Can Industries Strengthen Their Process Safety Management Programs?

To establish an effective and sustainable PSM framework, industries must adopt proactive safety measures.

Best Practices for Strengthening PSM Programs:

✅ Conduct Regular Risk Assessments – Perform Hazard Analysis and HAZOP Studies to identify vulnerabilities.

✅ Invest in Advanced Safety Technologies – Use automated monitoring systems for real-time hazard detection.

✅ Enhance Employee Safety Training – Conduct periodic safety workshops and drills to keep employees informed.

✅ Establish a Strong Audit Mechanism – Implement Safety Audits to ensure continuous compliance.

✅ Improve Emergency Response Readiness – Regularly update evacuation plans, fire safety drills, and first-aid procedures.

By prioritizing safety at every operational level, industries can create a secure, efficient, and sustainable work environment.

Conclusion: The Future of Process Safety Management in Industrial Safety

With industries evolving and operational risks becoming more complex, Process Safety Management is no longer optional—it is a critical necessity. Implementing a structured PSM framework helps businesses mitigate risks, ensure compliance, and enhance workplace safety.

Organizations must continually evaluate and improve their safety strategies, integrating technological advancements and expert guidance to maintain a zero-incident work environment.

By focusing on proactive risk management, industries can achieve long-term operational success and employee well-being.