Why Is HAZOP Study Essential for Industrial Safety?

Industrial safety is a crucial aspect of any facility that deals with hazardous processes, chemicals, or complex machinery. Ensuring a secure work environment requires a systematic approach to identifying and mitigating risks. One of the most effective methodologies used in risk assessment is the HAZOP Study.

What Is a HAZOP Study and How Does It Work?

A HAZOP (Hazard and Operability) Study is a structured and systematic technique used to evaluate potential hazards in industrial processes. It helps identify deviations from intended operations that could lead to safety risks, environmental damage, or production inefficiencies.

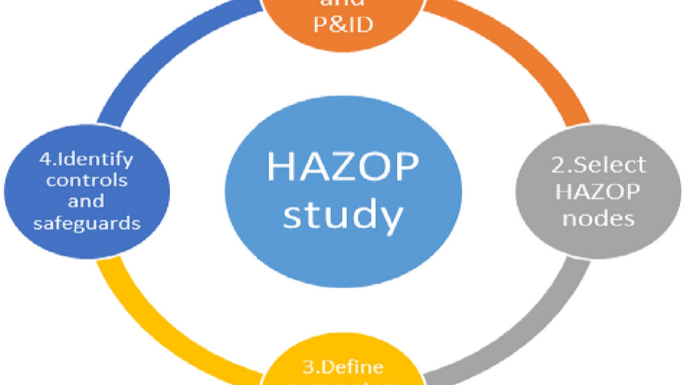

The process involves:

- Team Formation – A multidisciplinary team of engineers, operators, and safety professionals collaborate to analyze potential hazards.

- Process Review – The team examines the design and operating conditions of a process to detect potential risks.

- Deviation Identification – Using guide words like “more,” “less,” “as well as,” and “instead of,” deviations from normal operations are studied.

- Risk Assessment – Identified hazards are evaluated based on their severity and likelihood.

- Corrective Actions – Recommendations are made to eliminate or mitigate risks.

This structured approach ensures no critical risk is overlooked, making industrial facilities safer and more efficient.

How Does HAZOP Study Enhance Workplace Safety?

A HAZOP Study provides several benefits in industrial settings. Here’s how it enhances workplace safety:

1. Proactive Risk Identification

Rather than waiting for accidents to happen, a HAZOP Study identifies risks before they become incidents. By assessing possible deviations, industries can implement corrective measures in advance.

2. Improved Process Efficiency

Beyond safety, identifying operational inefficiencies through a HAZOP analysis helps optimize processes, reducing downtime and improving productivity.

3. Regulatory Compliance

Industrial safety regulations demand risk assessments to ensure workplace safety. A HAZOP Study aligns with industry standards, helping businesses meet compliance requirements and avoid penalties.

4. Prevention of Catastrophic Failures

Some industrial accidents result in major financial losses, environmental disasters, or even loss of life. By detecting weaknesses in process designs, HAZOP studies prevent catastrophic failures.

5. Enhanced Worker Safety

A well-executed HAZOP Study ensures employees are protected from hazardous conditions by mitigating potential risks in daily operations.

The Role of Fire Audits in Industrial Safety

Fire hazards are among the most significant threats in industrial environments. Conducting a Fire Audit is essential to assess fire risks, emergency preparedness, and fire protection systems. A fire audit evaluates:

- Fire suppression systems (sprinklers, extinguishers, alarms)

- Fire safety compliance with local regulations

- Evacuation plans and employee preparedness

- Potential ignition sources and preventive measures

When combined with a HAZOP Study, fire audits provide a robust framework for minimizing fire-related hazards in industrial settings.

Why Safety Audits Complement HAZOP Studies

A Safety Audit systematically reviews workplace safety practices to ensure compliance with regulations and standards. It identifies safety gaps and provides actionable recommendations.

A HAZOP Study focuses on process deviations, whereas a safety audit assesses overall safety protocols, equipment, and worker compliance. Integrating both ensures a more comprehensive risk management approach.

Process Safety Management: A Key to Industrial Safety

Process Safety Management (PSM) is a framework used to prevent hazardous incidents in industrial operations. It consists of 14 essential elements, including:

- Hazard Analysis – Identifying risks in industrial processes

- Employee Training – Educating workers on safety procedures

- Operating Procedures – Establishing guidelines for safe operations

- Emergency Planning – Ensuring readiness in case of accidents

PSM and HAZOP go hand in hand, providing a structured approach to eliminating potential risks.

The Importance of Hiring a Safety Consultant

A Safety Consultant plays a vital role in industrial safety by providing expert guidance on risk assessment, safety audits, and compliance strategies. Their responsibilities include:

- Conducting HAZOP Studies and risk assessments

- Evaluating workplace hazards and recommending preventive measures

- Assisting in fire audits and process safety management

- Ensuring regulatory compliance with industry safety standards

Hiring a safety consultant ensures that industrial facilities follow best practices in risk management and employee protection.

Conclusion

A HAZOP Study is an indispensable tool for industrial safety, providing a proactive approach to identifying and mitigating hazards. When integrated with fire audits, safety audits, process safety management, and expert guidance from a safety consultant, industries can create a safe and compliant work environment.

By implementing structured risk assessment methodologies, industries can significantly reduce operational risks, enhance safety, and ensure regulatory compliance.